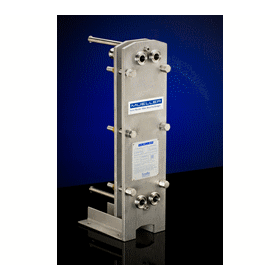

When you deal with Allied Heat Transfer, you get such experience. Our qualified engineers work with you to determine the thermal and mechanical design requirements for your equipment. Your exchanger will be custom-designed using the latest, industry-leading thermal and mechanical design software.

More than a product picked from a sales manual, when you work with Allied’s engineers, you get a tailored solution. The result? A correctly sized exchanger that performs as you need it to.

Service backed by substance

Allied’s engineering, design, drafting and quoting is all done in-house, as is most of its manufacturing. This safeguards quality and keeps costs low.

Part and Supply

Drawing on a large database of part numbers and comprehensive parts’ lists, and their wealth of knowledge, Allied’s engineers can advise you what parts you need and the surest, fastest way to obtain them. This will save you being asked a host of questions, which are often a hassle to answer.

Allied’s quotes are fast and accurate. Likewise, all of Allied’s spares are provided promptly, a result of stock being on-hand and spare parts coming directly from the Alfa Laval factory.

Maintenance

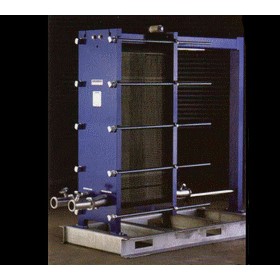

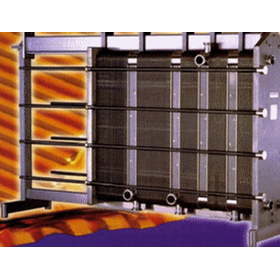

Any type of plate heat exchanger can be serviced, cleaned, regasketed, replaced at our East Coast and West Coast Workshops. Allied’s workshop staff are experienced in all aspects of heat exchanger maintenance & repair, which means they get it right, first time. Their cleaning systems (including ultrasonics or chemical bath immersion), inspection methods, assembly and testing procedures are all designed for optimum results that save your time and your money.

-280x280-state_7.jpg)