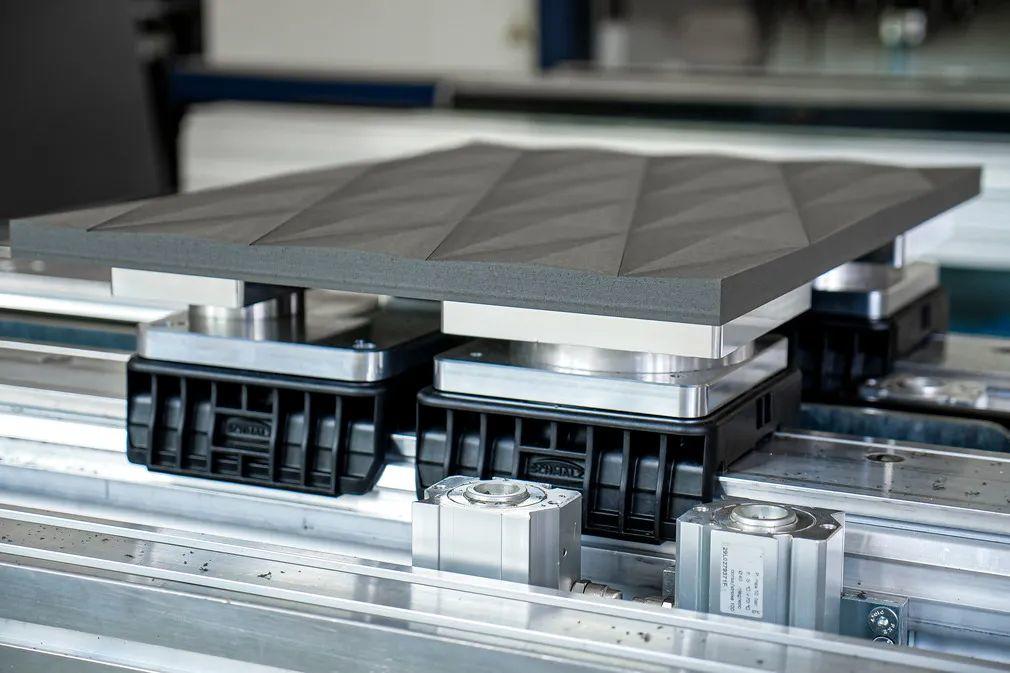

Schmalz has introduced new vacuum clamping systems tailored for CNC machining centers from Biesse and SCM Morbidelli. The VCBL-B-HD and VCBL-S6-HD vacuum blocks offer exceptional versatility, capable of securely holding both delicate components and demanding solid wood or solid surface materials. The heavy-duty versions provide enhanced reliability and efficiency.

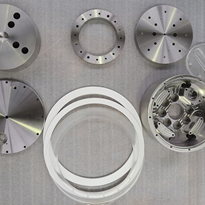

Durable and Flexible Aluminum Design

Crafted from robust aluminum, Schmalz’s vacuum clamping systems come in a sleek silver finish, designed for Biesse and SCM Morbidelli console tables. The VCBL-B-HD and VCBL-S6-HD vacuum blocks operate as hose-free systems, accommodating a diverse range of workpieces. They effectively hold thin components and heavy solid wood, including those with rough surfaces.

Optimized for High Cutting Forces

These vacuum blocks are engineered to withstand high cutting forces when machining solid wood, HPL (high-pressure laminates), and other laminates. Optional screw-mounted suction cups and cup mountings provide added stability during production. With strong holding force and lateral force absorption, these systems ensure reliable workpiece fixation, minimizing the risk of rejects.

Efficient and Adaptable Clamping

The integrated touch valve feature allows unused vacuum blocks to remain on the machine table, reducing setup times. The clamping equipment is highly adaptable, with rotatable suction plates that conform to various workpiece geometries. The flexible sealing accommodates rough surfaces and can be easily replaced without needing to replace the entire vacuum block.

Two Models, Multiple Applications

The VCBL-B-HD vacuum blocks are designed for Biesse systems and are available in heights of 48 and 74 millimeters. The VCBL-S6-HD vacuum blocks cater to SCM Morbidelli machines and come in heights of 75 or 110 millimeters. These blocks are also compatible with the Flexmatic machine table for automatic positioning and the Start-Pilot with position detection, with appropriate accessories.

Advanced Features with NFC Technology

An impressive feature of these new vacuum blocks is their NFC (Near Field Communication) capability. The suction plates for both models are rotatable and interchangeable, each equipped with an integrated NFC tag. This allows for easy access to technical data via smartphone, including dimensions, article numbers, serial numbers, and documentation. NFC technology streamlines service processes and ensures that accidental coupling with nearby components is prevented due to the limited effective range.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)