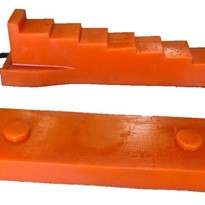

Manufactured from repurposed composite plastics that would have normally ended up in landfill, the entire BLOX range is engineered to provide exceptional performance, optimum safety and durability in some of the world’s harshest working environments including, mining, oil and gas, construction, heavy equipment maintenance industries, to name but a few.

Proudly Australian Made featuring hi-visibility orange finish for trip hazard prevention, sturdy carry handles for reduced pinch points, splinter-free for reduced puncture injuries, non-absorbent and environmentally sustainable. Specifically engineered and designed to replace older, weaker, unreliable and environmentally questionable wooden blocks and dunnage.

Benefits of the BLOX safety support and jacking blocks include: known working load limits with typical strength ranging from 68.8kg/cm2 to 122kg/cm2 (6.0 to 12.0 MPa) at 25°C; composite repurposed plastic construction for optimum durability, fire tolerance, UV resistant and resistance to gas, oil, chemicals and organic substances.

The BLOX are suitable for both active stabilising, where a person is working nearby, and for passive stabilising, where stabilisation is used to keep equipment and material off the ground for storage.

BLOX stabilising supports is an Australian first technology with significant environmental benefits:

- Reduction of waste plastic going into landfill, water systems and stock piles.

- One tonne of discarded plastic waste produces 120 of the BLOX BP122560LO (125 x 250 x 600) stabilising and jacking block.

- For every 1200 BLOX BP122560LO (125 x 250 x 600) stabilising and jacking block produced represents:

- 17m3 of finished timber not taken (approx. 30 trees)

- 8 tonnes of repurposed plastics used

- 1 tonnes of repurposed polystyrene used

Unlike wood alternatives, the BLOX range is load rated and warranted for 50 years against splitting, rot, termites and mould.

-160x160-state_article-rel-cat.png)