- Biotechnology

- Sterile pharmaceuticals

- Ultra-hygienic food processing

- Separation equipment

- Aseptic manufacturing

- Multi-product facilities

- Sanitary/hygienic production

- Sampling

Benefits

- Rapid de-contamination and product change-over

- Fully self-draining pump head: no hold-up of process liquid or cleaning agents

- External rotor fixing – no internal crevices

- Low-carbon 316L stainless-steel for maximum corrosion resistance

- Controlled-compression gasket-type joints and no O-rings in product contact

- Shaft seal design combines highest levels of containment with total product draining, no cavities, and front access for easy inspection and fast maintenance

- Standard surface finish: 0.8µm (150 grit), with 0.5µ (240 grit) and electro polish options

- Optional steam/sterile fluid barriers on joints, for true aseptic processes

- High efficiency to minimise damage to shear-sensitive low viscosity fluids

Capabilities

- Flow rates up to 44m³/hr (12 litres/second)

- Pressures up to Up to 20bar (290 psi)

- Temperature range: -30ºC to +140ºC

- Liquid viscosity range: 1 to 1,000,000 centipoise

- Ports: ½” to 4″ (13mm to 100mm)

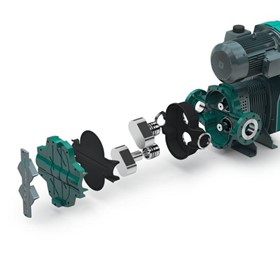

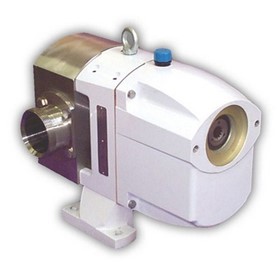

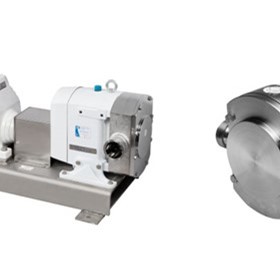

Design Features

- Ultimate Hygienic Standards – Tested and approved to the EHEDG (European Hygienic Equipment Design Group), CIP, SIP and Bacterial Tightness protocols. Full conformance to 3A Sanitary Standards 18-03 and 02-10 and utilising materials which meet the requirements of the FDA title 21, section 177.1550.

- Cleaner by Design – External rotor retention together with gasket type joints in place of O-rings reduce the number of potential product entrapment areas. In addition to this, the shaft seals are pulled forward fully in the product zone, all of which adds up to the ultimate in cleanability……every time!

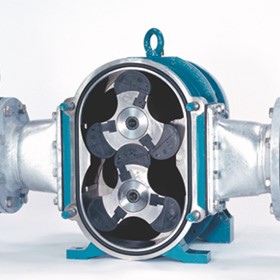

- Low Product Shearing – The bi-wing and 5 lobe rotor designs ensure high volumetric efficiency on low viscosity products resulting in low shear rates and low product damage.

- Rugged Design – This pump design utilises extremely large shaft diameters mounted in high specification taper roller bearings. These give maximum shaft stiffness to ensure no galling thus maintaining the pump’s CIP and SIP capabilities.

Options

- Seals – Front loaded single mechanical face type seals of hygienic design. Materials include carbon and silicon carbide.

Low pressure flushed seals utilise the same single mechanical seal with an additional housing. A low pressure flush liquid washes away crystallising products or liquids which ‘skin over’.

Double mechanical seals utilising all the components from single seals. Used for hazardous, toxic, highly abrasive or sterile products. - Certification – 3.1B Material Certification package. 3A Variants with Nitrile or EPDM elastomers and port options – Tri-clamp, IDF, 3A, DIN11851

- Connections – US and European standards including Tri- Clamp. All pumps available with 2 different sizes.

- Elastomers – USP Class VI, EPDM, Viton and PTFE product contact joints all in compounds conforming to the FDA CFR title 21 section 177.1550.

- Other options – Aseptic barrier end cover joints to maintain sterility of product during long cycle times. Electropolish or high polish internal surfaces to 0.5μm Ra (20 micro-inc Ra) for minimised cell damage and maximised cleanability.

PERFORMANCE CAPABILITIES

| 55 Series | ||||

|---|---|---|---|---|

| Pump Model | 55210 | 55320 | 55420 | |

| Port Size | (mm) (inch) |

12.5 ½ |

19 ¾ |

25 1 |

| Displacement (100 revs) |

(litre) (US gal) |

1 0.26 |

2.9 0.77 |

6.7 1.77 |

| Max Flow (per min) |

(litre) (US gal) |

16 4.2 |

44 11.6 |

67 17.7 |

| Max Pressure |

(bar) (psi) |

14 203 |

20 290 |

20 290 |

| Max Speed |

(RPM) | 1500 | 1500 | 1000 |

| Size LxBxH |

(mm) (inch) |

191x114x135 7.5×4.5×5.25 |

264x145x168 10.5×5.75×6.5 |

302x168x191 11.75×6.5×7.5 |

| PBareshaft Weight |

(kg) (lbs) |

8 18 |

19 42 |

26 57 |

| Temp | (oC) (oF) |

-30 to 140 -22 to 284 |

||

| Viscosity | (cP) | 1 to 1 million | ||

PERFORMANCE CAPABILITIES

| Ultima | |||||||

|---|---|---|---|---|---|---|---|

| Pump Model | LU42 | LU44 | LU52 | LU54 | LU62 | LU64 | |

| Port Size | (mm) (inch) |

25 or 38 1 or 1½ |

38 or 50 1½ or 2 |

38 or 50 1½ or 2 |

50 or 76 2 or 3 |

63 or 76 2, 2½ or 3 |

76 or 100 3 or 4 |

| Displacement (100 revs) |

(litre) (US gal) |

12.3 3.25 |

20.4 5.39 |

26.5 7.00 |

45.5 12.02 |

64 16.90 |

95 25.10 |

| Max Flow (per min) |

(litre) (US gal) |

123 32.5 |

204 53.9 |

254 70.0 |

437 120.2 |

461 121.8 |

684 180.7 |

| Max Pressure |

(bar) (psi) |

15 217 |

8 116 |

15 217 |

8 116 |

15 217 |

8 116 |

| Max Speed |

(RPM) | 1000 | 1000 | 1000 | 1000 | 720 | 720 |

| Size LxBxH |

(mm) (inch) |

285x223x182 10.75×8.75×7.75 |

301x223x182 11.75×8.75×7.75 |

386x249x208 15.25×9.75×8.25 |

414x259x213 16.25×10.25×8.25 |

463x328x249 18.25x13x9.75 |

492x328x254 19.25x13x10 |

| PBareshaft Weight |

(kg) (lbs) |

23 51 |

25 55 |

38 84 |

41 90 |

70 154 |

75 165 |

| Temp | (oC) (oF) |

-30 to 140 -22 to 284 |

|||||

| Viscosity | (cP) | 1 to 1 million | |||||

-375x300-280x280-state_7.jpg)