Mastering Precision: Why Every Workshop Needs a Quality Sheet Metal Bender and Press Brake

In today’s competitive manufacturing landscape, precision and efficiency are key. Whether you’re a large-scale manufacturer or a small workshop, investing in the right equipment can make a world of difference. Two indispensable tools for any metalworking business are the sheet metal bender and the press brake. But what makes these tools so essential, and how can you choose the right ones for your needs? Let’s dive in.

The Role of Sheet Metal Benders in Metalworking

A sheet metal bender is a versatile tool that helps shape metal sheets into various forms. Whether you’re crafting simple brackets or intricate components, a high-quality sheet metal bender ensures accuracy and repeatability. The tool is designed to bend metal sheets without causing damage or compromising the material’s integrity.

Key Benefits of Using a Sheet Metal Bender

- Precision: Achieve clean, uniform bends that meet exact specifications.

- Efficiency: Reduce manual labour and speed up production time.

- Versatility: Handle a wide range of metals, including steel, aluminium, and brass.

At Tool Tech, we offer a variety of sheet metal benders that cater to different business sizes and requirements. Whether you need a compact solution for your small workshop or a heavy-duty model for industrial applications, we have you covered.

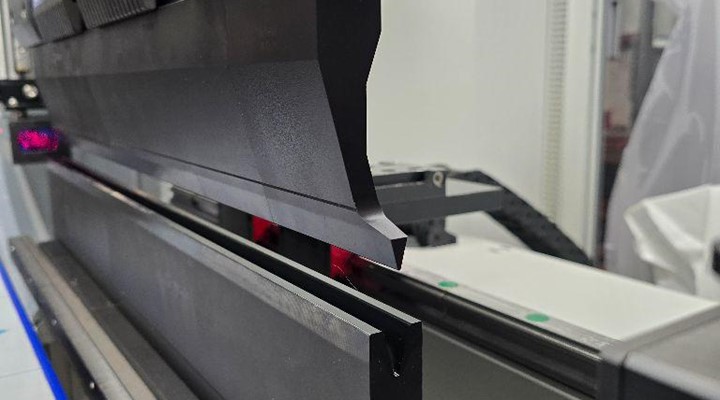

Why a Press Brake is a Must-Have

While a sheet metal bender is excellent for smaller tasks, a press brake is essential for heavy-duty projects. This machine uses a hydraulic or mechanical pressing system to bend metal sheets into precise angles, making it perfect for large-scale manufacturing or intricate designs.

Features That Set a Press Brake Apart

- Advanced Controls: Modern press brakes come with CNC (Computer Numerical Control) technology, allowing for automated and highly accurate operations.

- High Capacity: Capable of bending thicker and larger metal sheets.

- Durability: Built to withstand the rigours of industrial use.

At Tool Tech, we understand the importance of reliable equipment. That’s why we provide top-of-the-line press brakes to help businesses across Australia stay ahead of the curve.

Choosing the Right Equipment

When selecting a sheet metal bender or a press brake, consider the following factors:

1. Material Type and Thickness

Different tools are suited for different metals and thickness levels. Ensure your chosen equipment can handle the specific materials you work with.

2. Production Volume

For high-volume production, opt for automated or CNC-enabled models to save time and labour.

3. Budget

While it’s tempting to go for the most advanced model, consider your budget and the return on investment (ROI). Tool Tech offers a range of affordable yet high-quality options.

4. Space Constraints

Evaluate the available space in your workshop to ensure the equipment fits comfortably.

Maintenance Tips for Longevity

Both sheet metal benders and press brakes are significant investments, so proper maintenance is crucial:

- Regular Cleaning: Keep the equipment free from debris to ensure smooth operation.

- Lubrication: Periodically lubricate moving parts to prevent wear and tear.

- Inspection: Conduct regular inspections to identify and address any potential issues early.

Why Choose Tool Tech?

At Tool Tech, we pride ourselves on offering high-quality tools and machinery designed to meet the diverse needs of Australian businesses. Here’s what sets us apart:

- Extensive Range: From entry-level models to advanced CNC press brakes, we have something for everyone.

- Expert Support: Our team is always ready to guide you in choosing the right equipment.

- Competitive Pricing: Enjoy premium quality without breaking the bank.

Conclusion

Investing in a reliable sheet metal bender and press brake can transform your workshop’s productivity and quality. With their precision, efficiency, and durability, these tools are invaluable assets for any metalworking business. At Tool Tech, we’re here to help you make the right choice for your needs. Explore our range today and elevate your metalworking game.

Take the first step toward precision and efficiency—visit our website or contact us for more information!

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)