The Unseen Dangers of Dust

Industrial dust can come from various sources, produced as a byproduct of processes like cutting, grinding, drilling, sanding, and crushing materials such as metals, minerals, grains, and chemicals. These processes break materials down into smaller particles that become airborne, creating industrial dust.

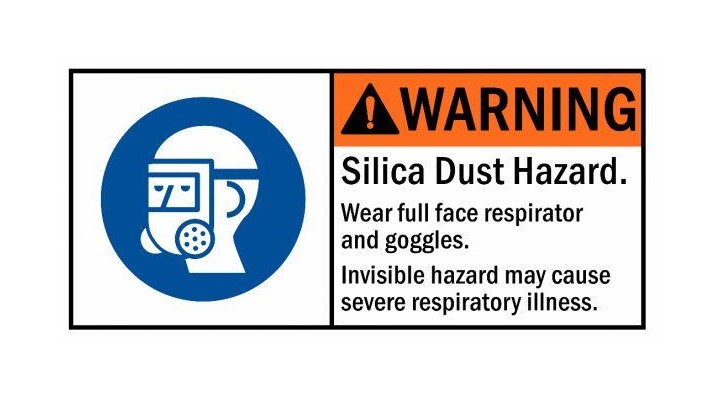

Silica dust, or crystalline silica, consists of microscopic particles of silicon dioxide, a common mineral in many natural materials. It becomes particularly hazardous when it becomes airborne during typical industrial and construction activities. Inhalation of these particles can lead to severe respiratory health problems.

Crystalline silica is prevalent in building materials due to its strength, durability, and heat resistance. While these properties are beneficial, they also result in the production of harmful silica dust during activities like cutting, grinding, drilling, or crushing materials such as bricks, blocks, pavers, tiles, mortar, concrete, cement products, and natural substances like rock, sand, and clay.

Using proper handling techniques, protective equipment (PPE), and adequate ventilation are crucial in minimizing exposure and associated health risks. So too is the application of water during cleaning processes, such as wet sweeping, to prevent dust from becoming airborne.

The Importance of Dust Control

Effective dust control is vital for maintaining indoor air quality and preventing pollutant accumulation, which can harm workers and visitors. A contaminated workplace can lead to staff absenteeism and reduced productivity, exacerbating the challenge of finding temporary staff in today’s market.

Airborne dust particles can cause respiratory irritation, asthma, and chronic illnesses such as silicosis, pneumoconiosis, and chronic obstructive pulmonary disease (COPD).

Dust control also fulfills environmental and community responsibilities by minimising the impact on nearby air quality. Additionally, dust accumulation on machinery and equipment can impair performance, leading to breakdowns, costly repairs, and downtime. Dusty surfaces can also cause forklift tires to slip, creating a hazardous environment.

In food production, dust must be controlled to prevent contamination, meet hygiene standards, pass audits, and uphold supply contracts. Dust can also pose a fire hazard if it is combustible and ignites under certain conditions.

Beyond health, safety, and productivity concerns, effective dust control enhances the overall presentation of the premises.

The Health Risks of Dry Sweeping

The vigilant Environment Protection Authority (EPA) has intensified its focus on dust control compliance. Complaints are thoroughly investigated, and businesses failing to manage silica dust, thereby endangering worker health, can face heavy fines and enforceable warnings, potentially even site closures.

Health and environmental organisations deem the safest way to clean dusty sites containing silica dust is by dampening it to prevent it from becoming airborne, using a wet sweeping process rather than dry sweeping. Dry sweeping can stir up invisible dust clouds, creating hazardous conditions for workers.

Type M and Type H filters in vacuum sweepers are common dust management methods. However, finer filters clog quickly with dust particles, making them inefficient. Blocked filters then stir up more dust, endangering operators and nearby workers, effectively turning sweepers into dust distributors.

Breathe easier: tackling dust hazards with wet sweeping

Wet sweeping is the most effective solution for controlling industrial dust, especially hazardous silica dust. Unlike dry methods, wet sweeping prevents particles from becoming airborne by using water, turning dust into a mud-like liquid. This liquid is then extracted using powerful suction and squeegees, thoroughly removing dust without dispersing it into the air.

This approach is crucial considering the risks posed by silica dust. Even vacuums with HEPA filters can quickly clog with small particles if not maintained regularly, making wet sweeping the most efficient and convenient choice for large spaces.

Floor cleaners like the Conquest CC1200 and HD 46TC further support wet sweeping, adeptly sweeping and scrubbing in a single pass. This method not only ensures compliance but also protects staff health, the environment, the community, and enhances operational efficiency.

Using combination floor cleaners such as the CC1200 for wet sweeping promotes efficiency over large areas by sweeping, scrubbing, and drying in one pass. This saves time and reduces labor costs.

Post-cleaning waste disposal is safer and more efficient with wet sweeping machines, as the waste is solidified in liquid form and will not become airborne upon disposal.

Reducing the risks of industrial dust with wet sweeping as the ultimate solution

By maintaining a clean, dust-controlled workplace with wet sweeping, you promote operational continuity, minimise maintenance costs, adhere to regulatory standards, and protect the health and safety of your staff and visitors. Your commitment to workplace cleanliness translates to a commitment to your team’s well-being.

Request a Demonstration

Take control of dust in your workplace with Conquest behind you all the way. Request a no-obligation site assessment to get started.

-205x205.jpg)