Customer: Carter Holt Harvey (CHH) – Gympie, QLD.

Application: Geared Drive for G1 Press Spider No. 1

New or Replace Existing: Replace Existing Set Up, due to nil availability of existing units and new technology available for a more compact arrangement

Current Arrangement:

1st stage:

- Asea In-Line HM114-210AK 6.22:1 C/W 4Kw Brake Motor

- Sprocket Fitted To Output Shaft: 35 tooth

- Sprocket Fitted To Input Shaft (Worm Box): 40 tooth

- Overall Sprocket Ratio: 1.14:1

2nd Stage:

- Borg Warner Worm Drive 60:1

Total Overall ratio = approx: 425:1 giving an output speed of approx. 3.5RPM

Engineering Requirements: A new base plate was required to match existing centre height and a Solid Plug-In Output Shaft was required to match the existing output shaft.

Pricing Guideline: Units need to be replaced due to existing units no longer being readily available, as complete units or as spare parts. Ultimately a unit of equal or less cost was desired. The Sumitomo BBB replacement unit was the perfect fit as it costs a lot less than the existing unit, is far more compact and runs far more efficiently and quietly.

Special Considerations: Ratio. The existing unit actually rotates at approx. half of the speed that it can ultimately do, due to changes on the actual machine itself.

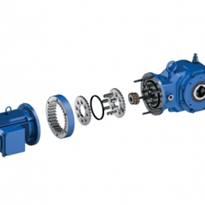

Solution: CHH looking to replace existing set up with a single right angle drive. After determining the details of existing set up a decision was made to go with an E Size Buddybox with a 207:1 Ratio. This ratio gives an output speed of approx. 7RPM, which not only improves the efficiency of the Spider Press, but gives the same output speed of a number of other Size E Buddyboxes on site. By having common geared units on site, it eliminates the need to carry extra spare parts for critical machines.

Utilising the in-house engineering capabilities of Carter Holt and Harvey, a new base plate to match existing centre height was manufactured along with a new Solid Plug-In Shaft, that was easily fitted into the Sumitomo Buddybox and is easily removed for future maintenance.

New unit supplied was part LHYJM5-3E175-Y1-B-207 C/W 4Kw Weg 4Pole Brake Motor

Unit was installed without any problems due to the engineering input of both the CHH engineering team and the local Sumitomo Sales Engineer, Mr Guy McAuliffe.

All of the CHH team involved in production utilising this piece of machinery have since commented on how quietly the new Buddybox arrangement is running. The electrical engineering team have also commented on the reduction of energy consumption (electricity) due to the far superior overall efficiency of the Sumitomo Buddybox.

CHH have another 3 off these machines onsite which they will convert in the near future, utilising the Sumitomo Buddybox.