What is filter integrity testing?

Regardless of what industry you work in, it's important to conduct process filter integrity testing to ensure optimal conditions for your production. This is especially true for applications involving human contact like food and beverage, cosmetics and pharmaceutical.

In short, integrity testing is a way to ensure the sterile grade filter elements used are integer and do not show any leakages. The only correct way to check this integrity would be to measure the retention of bacteria and other microorganisms. Since this is a highly complex measurement, alternative methods have been developed and validated. Means, the values given in the product documentation ensure that the retention of the filter cartridge towards microorganisms fulfills the FDA requirements for sterile grade filter elements.

With that, it's advised to test after every sterilization cycle before initiating production. This is known as pre-use post sterilize integrity testing (PUPSIT). You also should check filter integrity before and after installation to make sure everything is connected properly.

There is equipment available to conduct onsite testing when needed. Alternatively, we offer it as a service. Read on to learn more about the types of filter integrity testing. We'll also explain whether it makes sense to invest in testing equipment for your facility.

Testing procedure and methods

The right testing method one will choose depend on the type of filter used. If you're evaluating a hydrophilic filter, you may choose between a Bubble Point Test, a Diffusional Flow or a Pressure Hold Test. Hydrophobic filters might be assessed by a water intrusion test or a so called DEHS Test.

It's also worth mentioning that some methods involve in-situ wetting first. This is either done with water, alcohol, or a mixture of both. Before starting any test, you want to make sure the filter cartridge is installed correctly in the housing.

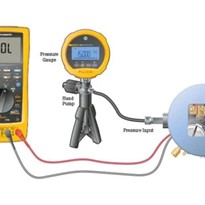

It's important all connections are tight before proceeding. This is because of the varying levels of liquids and air pressure needed to properly conduct filter integrity testing.

Bubble Point Test

The Bubble Point Test is a commonly used integrity test for membrane filters. Prior to the test the filter elements need to be wetted with e.g., water, so all pores of the membranes are covered with a thin water layer.

Afterwards the elements will be exposed to air or nitrogen. By increasing the gas pressure, a proportional increase of a diffusive gas flow through the wetted filter pores might be monitored. By a further increase of the pressure applied, the thin water layer in the membranes will be blown off and the gas flow snowballs. This specific pressure is called the “Bubble Point” Pressure and directly correlates with the smallest pores of this specific filter element. In case the gas flow occurs at a lower pressure level the membrane is considered defect.

Diffusion flow & Pressure Hold Test

The diffusional flow test is quite similar to the previously explained Bubble Point Test. Also, for this test, the hydrophilic membrane filters are wetted and then exposed to a gas like air or nitrogen. However, the outside pressure applied is only about 80% of the pressure applied for the Bubble Point Test. At this pressure the air flow through the thin water layers covering the pores is measured. If the flow rate of the diffusing gas is higher than stated in the filter documentation the filter element is considered defect.

A deviation of this test is the so called “Pressure Hold Test”. This specific test measures the pressure loss of a wetted filter element inside a housing over a specific period of time. If the pressure loss is higher than a calculated value the filter is considered defect. This test might also be used to check the integrity of filter housings.

Water intrusion Test

The Water Intrusion Test (WIT) is a commonly used test for hydrophobic membrane filters like PTFE membranes. To test such an element the outside of the filter cartridge will be wetted with water. Afterwards, a pressure (usually 2.5bar) is applied to the entire system. The water diffusing through the hydrophobic membrane raises a pressure drop on the upstream side which can be monitored. A hydrophobic membrane without any leakage shows a flow of 5 – 11ml per 10“ element within 10 minutes. Higher values usually refer to potential damage or a potential hydrophilisation of the membrane.

Onsite filter integrity testing

Depending on the size of your facility, you may wish to invest in onsite equipment to conduct integrity testing. If you choose to do this, you'll want to make sure to follow proper care protocols. This is because testing involves liquids and aerosols. Also, regular calibration is needed.

It's also important to check to make sure the testing equipment is capable of handling the desired testing method. As mentioned, there are three types of standard tests. Certain equipment can be more suitable for each one. Much like running any machine in your facility, you'll want to evaluate overall efficiency.

Alternatively, as pointed out above, we offer filter integrity testing to customers. No matter what you need, we're here to help and can provide expertise on what makes the most sense. To get started, feel free to reach out. Our team is available to answer any questions you may have.

-160x160-state_article-rel-cat.png)