To avoid a system failure, more and more condition monitoring systems and solutions for predictive maintenance are called for. They ensure that maintenance work can be scheduled, and unplanned failures avoided. For this, systems for condition monitoring - such as igus i.Sense from Treotham – are the first development stage. Predictive maintenance - like the igus i.Cee system - is the next step towards implementing a comprehensive maintenance concept.

Conventional predictive maintenance involves the replacement of moving components such as energy chain systems or plain bearings at regular intervals, which is often shorter than the expected service life. However, this means that the components are replaced when they are still operational. If, however, they are replaced shortly before they reach the end of their actual life, the service life can sometimes be significantly extended, often even doubled. This then halves the costs and reduces the maintenance effort - without compromising reliability. In these cases, predictive maintenance systems that work with IoT are worthwhile. They monitor the condition of the components while predicting their service life during operation. If irregularities occur before the specific end of service life is reached (e.g. due to an accident or the presence of contaminants), the system can detect these irregularities and issue a warning message. The user is then able to eliminate the unusual operating condition before major damage occurs.

Minimise service and maintenance costs

For large energy chain systems, compliance with the maintenance instructions is essential for maximum service life. For example, the so-called igus i.Cee system from Treotham reminds the customer of upcoming inspections or maintenance work, similar to a car. This information is provided according to use, so that longer maintenance intervals are possible with less use, thus saving costs. This also applies to plain bearing applications. Here, adherence to the maintenance instructions prevents costly damage to shafts or the bearing seat. An increasing number of production plants are recognising the savings potential offered by networking machines and machine components at the data and IT level, right through to cross-company networking through overarching standards, such as OPC UA. Here there are further (cost) advantages in the use of energy chain and plain bearing systems with "built-in" predictive maintenance.

All sensor data - e.g. the calculations of the individual service life and the resulting notification - can be passed on to higher-level IT systems and evaluated or documented there. This includes management execution systems (MES), zero-downtime systems (ZDT) and software for company-wide maintenance.

Smart "preventive maintenance" - with i.Cee

As an intelligent "preventive maintenance" system, i.Cee consists of three levels: sensors, hardware and data collection/evaluation. At the heart of the system is the software. It creates the conditions for an intelligent, condition-based and individual service life calculation and continuous monitoring of an energy chain or plain bearing system. The i.Cee software calculates the service life of the polymer component on the basis of the actual load. This is how it works: when the operation or software is started, the service life is compared with the algorithms of the current online service life calculator. The manually recorded environmental and movement data is applied, and the double strokes and/or kilometre readings are transferred to the software. It converts the data in terms of days. This results in the service life up to the recommended replacement, assuming the anticipated movement data with 24/7 use and constant impact of the maximum environmental data.

Learning software

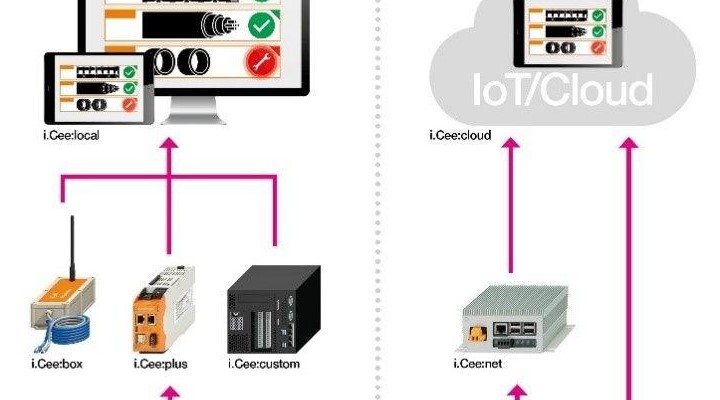

When commissioning the i.Cee System, the "worst-case scenario" is assumed, which is quickly put into perspective with the service life and the amount of real data collected. During operation, the system records the actual loads of the application in real use - e.g. intermittent operation and pauses/interruptions as well as, depending on the used sensor technology, temperature fluctuations, vibrations, lateral accelerations, chemical influences, abrasive media and so on. On this basis, the remaining service life is continuously recalculated - assuming the actual motion and load profile for further operation. If an Internet connection is available or i.Cee:net is used (see diagram), the online service life calculators of the components used are regularly queried at the same time and the display of the remaining service life is adjusted accordingly. When using i.Cee:local without an Internet connection (see diagram), if there is a serious deviation in the movement and environmental data, a temporary, manual query is requested from the customer's system in order to adapt the service life calculator to the actual conditions.

Sensors record real operating data

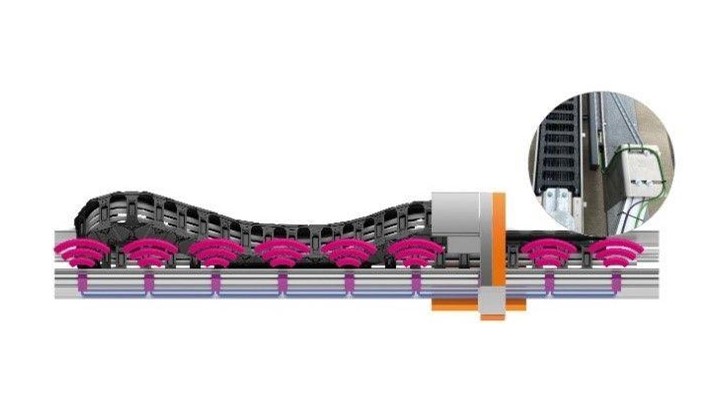

Abrasion and wear sensors, which are also installed in or attached to the igus products used (e.g. in the sliding feeder, in the pin-bore diameter or in the side wall), ensure a further comparison with the real conditions to which the respective igus product is exposed in the application. The sensors transmit information on the percentage lifetime status of the polymer components subject to abrasion. This sensor information "overwrites" the given calculations so that the forecasts become increasingly more accurate as the operation progresses and change from a "worst-case scenario" to an adaptive, learning scenario.

Provide inspection proposals and real-time information

Based on the calculations shown above, the customer receives information for inspection and maintenance planning for selected igus products, based on the maintenance recommendations provided by the empirical values gathered over several years in the field of energy supply and bearing technology. Both the above-mentioned sensors for service life calculation and the i.Sense sensor units for condition information provide data from which, in many cases, indicators for premature wear of the product or the risk of product failure can be determined at a very early stage. Based on the experience gained in the industry's largest test laboratory for plain bearings and energy transmission solutions, which is spread over 3,800 square metres, and in combination with self-developed algorithms, the system alerts and informs the user at an early stage about possible failure risks.

The i.Cee software calculates the service life of, for example, energy chain systems based on the actual load. That way, the maintenance engineer can efficiently plan system performance and maintenance work.

The i.Cee concepts: when i.Cee:local is used, the data does not leave the company network at any time, as the i.Cee software communicates only within the networks you want it to. With the Internet-based i.Cee.cloud solution, the data is transmitted directly to the cloud and can be called up via a browser dashboard. When doing so, the data stops off at the i.Cee:net, a so-called data concentrator.

Abrasion and wear sensors, which are also installed in or attached to the igus products used, allow for a further comparison of the measured data with real conditions.

-160x160-state_article-rel-cat.png)