KVA demand is directly related to the Power Factor of the electrical – electronic equipment installed. Some Electrical equipment has poor Power Factor. For example, SCR – Thyristor controlled rectifiers. When the output voltage is reduced from the rated output, the Power Factor changes to very Poor, possibly down to 0.25.

KVA demand increases as the Power Factor decreases, say from very good, PF 0.95 down to a very poor PF 0.25

So if possible buy electrical equipment that has a very Good Power Factor, which is normally between 0.90 to 0.95 and which is maintained between these two levels, especially when the output voltage of the rectifier is reduced. This will keep the KVA tariff costs lower, ensure the installation complies with regulations and possibly avoid having to purchase costly Power Factor correction equipment.

Power Factor correction

This infosheet contains information about:

- the definition of Power Factor

- how to correct or improve Power Factor in a workplace

- the advantages of a good Power Factor.

Introduction

Essentially, it is a measure of how effectively electrical power is being used by a system. A poor Power Factor indicates ineffective utilisation of electricity, while a good Power Factor indicates effective electricity and asset utilisation.

A simple analogy for Power Factor is to relate it to a garden hose. In ordinary circumstances, if you need 10 litres of water per minute to come out at the end of the hose, the tap should be turned on to deliver that amount of water. But if your hose leaks, is squashed between rocks, or is kinked because it is cheap, you will experience a drop in pressure. To achieve your target of 10 litres/minute, therefore, you need to turn up the tap and force more water through the hose. That is Power Factor correction.

Types of power

In most situations, a load on an electrical distribution system can be put into one of three categories:

- resistive

- inductive

- capacitive

In modern industrial, shop and office environments the most common of these is the inductive load. Examples include transformers, fluorescent lights and AC induction motors. These types of equipment use windings in order to operate. Through the proximity or movement of the windings an electromagnetic field is produced which allows the motor or transformer to function. While an inductive load uses energy in order to do its work, it also needs a certain amount of energy simply to function properly.

So, there are two distinct types of power needed for an inductive load to operate

- active power (measured in kW) which actually performs the work

- reactive power (kVa) which sustains the electromagnetic field and does no actual work.

The apparent power of a system is the total power consumed in operating that system, or the combination of active power and reactive power.

Power Factor

What is Power Factor?

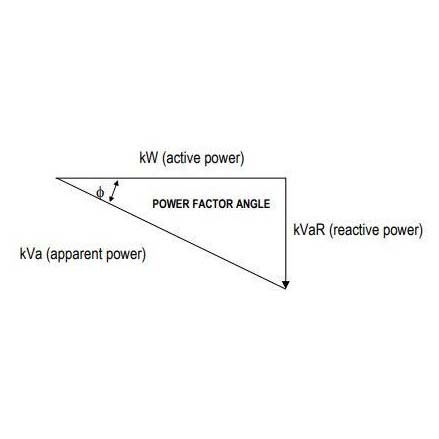

Power Factor is the relationship between the active power and the apparent power. The relationship between the types of power used to run a system is usually shown as a right-angled triangle. Note that active power is shown at right angles to reactive power, sometimes known as ‘waste’ because it is out of-phase, and does no useful work.

Power Factor is usually given as a number between 0 and 1 and is equal to the ratio of reactive power to active power, or Cosine f, as shown above. The higher the number, the more efficient the system. Thus, a system with a Power Factor of 0.9 is much more efficient than one with a Power Factor of 0.6.

Correcting poor Power Factor

Poor Power Factor should be corrected as it substantially increases costs. The overseas market reveals that where open electricity markets have been introduced one of the key areas of competition is between the supply utilities. In order to maintain their competitiveness, suppliers use two main strategies: reduce generation costs, and introduce ‘user pay’ regimes. That’s where Power Factor comes in.

A system with a low Power Factor (for example 0.6) requires the supply company to feed much more power into the distribution system so its customers can operate their equipment and appliances. Power companies can do a lot in their part of the system to raise the Power Factor closer to the ideal of 1.0. This means they don’t need to buy as much power from the electricity generation companies.

The difficulty comes in trying to make sure that their customers also have efficient systems with a high Power Factor. In states other than Victoria this has been achieved by charging customers on the basis of kilovolt amps (kVa), rather than on the traditional basis of kilowatt hours (kWh). This is a better measure of where the current generated is ultimately used. Tasmania, NSW and Western Australia have introduced some form of kVa or Power Factor electricity tariffs.

The Victorian distributors TXU (formerly Eastern Energy) and United Energy have introduced Power Factor charges into their network tariffs.

An example

Suppose there are two companies, A and B, that both use 500 kW annually. Company A has a Power Factor of 0.5, which means that it will use 1000 kVa annually. As a result, Company A ends up paying for a huge amount of power that it doesn’t use and which ends up as waste. Company B, on the other hand, has a highly efficient operation with a Power Factor of 0.9. It will be charged for only 555 kVa annually—

slightly more than half the electricity costs paid by Company A.

Effect on equipment

If the Power Factor of your system is low it uses more power than it needs to do the work. This can result in:

- excessive heat being generated, which can damage or shorten the life of equipment

- extra maintenance costs

- the potential for fires in extreme situations

- low voltage conditions which result in:

- sluggish motor operation

- dim lights (and the resulting quality and safety problems).

Applications

Typical applications that exhibit low Power Factor include air compressors, plastic extruders, machine tools, stamping presses and other industrial equipment.

Power Factor choices

Power Factor correction can be done when you are moving, building or leasing new premises. In this case you should ensure that your assessments of power costs include an analysis of Power Factor. In the near future you will probably be charged according to your Power Factor, particularly if you are a large user.

Power Factor correction can also be improved in existing facilities. Initially, you should measure the Power Factor at your workplace and discuss your options with your power supplier or consultant.

The use of Power Factor correction equipment has a number of advantages:

- In the form of a capacitor bank, it can be installed as close as possible to the meter point or the equipment that is the main culprit. This reduces the total current supplied by the electricity utility to your premises, but has no detrimental impact on plant.

- It has often been used to increase the power-carrying capacity of long cables. For example, new equipment may need to be installed which will overtax the amp rating in existing underground cabling.

Instead of replacing cables or installing new switchboard equipment—an expensive task–it is possible to increase capacity through Power Factor correction equipment. - It can be an economical solution to the problem of filtering out the spikes that cause equipment failure. An increase in the use of electronic equipment in offices and manufacturing situations means that this is an expensive problem that needs to be dealt with.

- Installing filter reactor equipment in series with the capacitor bank increases the continuity and integrity in your supply. This results in fewer fluctuations and circuit breaks, and reduced equipment damage. Installing capacitors will have a typical pay backperiod of one year.

Conclusion

Power Factor correction is an important way for a site to reduce its energy costs and significantly increase electrical switchboard capacity. In order to find out more about the impact of Power Factor correction on your bottom line, talk to your supply utility, or an experienced energy consultant.