When a semi-liquid product sticks to process lines and gets washed down the drain, so do profits. You want every ounce of your yogurt, pudding, or pharmaceutical to end up in the filling machine. So, like most processors, you may use a product recovery system to salvage anything left behind in piping.

Product recovery commonly involves a “pigging system.” This is a flexible cylinder with a silicone seal end that is pushed through the pipe to force remaining product out the opposite end. The force behind these systems is typically an inert utility like compressed air or water.

Recovering a product does little good if it spoils the entire batch. Spoilage can happen if an imperfect seal or crack in the pigging apparatus admits impurities from utility water or compressed air, and those impurities breed in the warm, moist environment. In addition, the next batch of product will travel through the same processing pipes and encounter anything deposited there. Because of this food-contact risk, best practices are to use sterile air or sterile water for this food manufacturing process.

How are sterile water and air produced?

There are several methods used to generate sterile air or water in food and beverage processing:

- reverse osmosis (RO),

- pasteurization,

- ultraviolet (UV) light sterilization,

- ozonation, and

- micro-filtration (for compressed air or water).

There are pros and cons to each method. RO systems have a delicate membrane that can be costly to replace, so they are often reserved for ingredient water. Pasteurization, UV sterilization, and ozonation are all effective, but add a separate process step.

Micro-filtration is becoming a recognized alternative for producing sterile water or air. The right micro-filter complies with 3-A standards and has cost advantages, since the sterilizing element can be integrated right into the process line. Micro-filtration produces pasteurized-equivalent water for a number of uses, including process recovery and clean-in-place systems.

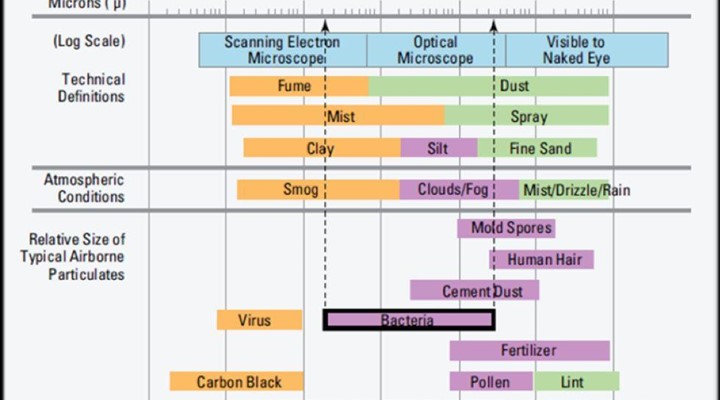

By pharmaceutical production standards, a sterile-grade air or water filter must have a consistent pore size of 0.2 microns in diameter and trap 99.99999% of all pathogens. (The smallest bacteria are 0.2 microns.)

Before you purchase a filter, carefully check its technical data sheet for micron size of 0.2 and look for a log reduction value of 7, the necessary retention. Not all filter manufacturers meet industry guidelines in this regard.

Work with a supplier such as Donaldson that follows the highest independent standards for air or liquids used in food contact or ingredient applications.

What constitutes sterile filtration?

To produce sterile air or water by pharmaceutical standards, a filter must have a consistent diameter pore size of 0.2 micrometers and remove 99.99999% of all particles in that size range.

On the filter’s technical data sheet, this performance is represented as a “0.2 micron absolute-rated filter with a log reduction value (LRV) of >7.”

By contrast, nominally rated filters have approximate pore distribution, and are not suitable for sterile utility production. Nominal filters are generally acceptable for non-sterile applications, such as pre-filtering steam boiler feed water.

Optimal design and maintenance of sterile micro-filtration

Donaldson recently collaborated with a leading yogurt company that converted all of its product recovery systems in plants around the world to cartridge micro-filtration.

Here are some important practices to observe if you want to use micro-filtration for similar product recovery purposes:

Protect micro-filters with pre-filtration

Trapping hard particulates can prematurely wear out the micro-filter, which is intended primarily for microbes. Because this element is costly, protect it with a series of pre-filters designed to filter all forms of sediment.

How many pre-filters your air or water needs depends on the quality of the source. Every municipal water supply is different and filtration needs may change seasonally as the water table rises and lowers. But in general, start filtration from the city water source with a 100- or 50-micron pre-filter, then graduate to finer filters in 10-micron increments. A 1-micron pre-filter is recommended just before water or air hits the final micro-filter.

In a compressed air system, the potential contaminants also include oil and condensed water in addition to sediment and microorganisms. Just as you would on a water line, used staged filtering to produce clean, dry air. Condition the air with lower-cost pre-filters and progressively refine it with finer-micron filters. Near the air’s point of use, the final micro-filter should be dedicated to filtering bacteria at a high efficiency.

You can get by with fewer elements, but your final micro-filter will face a greater risk of clogging or premature wear. An optimally designed filter sequence helps extend filter life and so ultimately supports lower total cost.

Plan filter location based on risk

If your plant has multiple points of use for sterile air or water, place prefilters on the larger utility lines and final micro-filters on branch lines as close as possible to the point of use. Exact placement will depend on available space in your plant.

In the best-case scenario, a process has a compact footprint because shorter pipe distances lower contamination risk. If you have 1,000 feet of carbon pipe between the last pre-filter and the final filter, that constitutes 1,000 feet of potential carbon deposits, rust, scale, and debris that could reach your expensive final filter. In that situation, plan on additional pre-filters for longer pipe lengths. Perform a risk analysis for each of your sites and design your system to minimize the risks.

Maximize filter life with quality technology

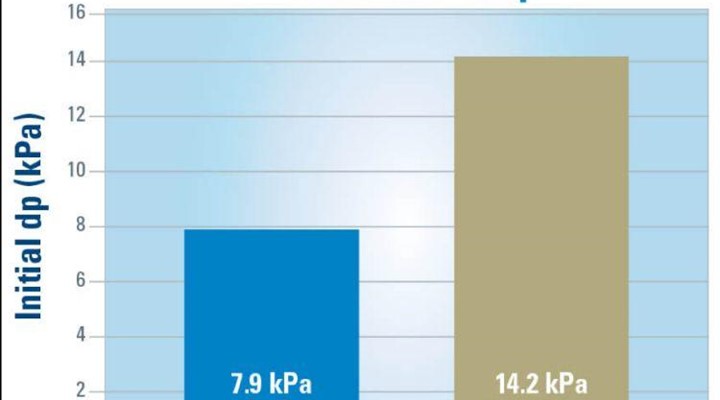

The cost of a filtration system is determined in large part by how long the elements last. Pre-filters expire when they clog. To detect a blockage, place pressure gauges upstream and downstream from the filter and change the filter at a predetermined pressure drop.

The micro-filter is different. If you’ve protected it with pre-filtration as recommended, you shouldn’t need to change a micro-filter due to clogging. But you do need to periodically kill the bacteria that build up on the membrane. This is usually done with steam-sterilization. Heat stress on the filter limits the number of sterilization cycles it can tolerate. Change the element when it reaches the maximum number of cycles recommended by the manufacturer.

Clearly, there is a cost advantage to using elements that tolerate the highest number of steam cycles—an area where Donaldson filters excel. Donaldson LifeTec® Liquid Micro-Filters, with PTFE membranes, have 20 percent more filtration media to support high flow rates. Their rigid support cages stand up to elevated temperatures. For compressed air, Donaldson P-SRF V air filters are available.

Donaldson tests show they last up to 160 sterilization cycles, versus 100 to 150 for the nearest comparable filter, with a log reduction value of 9 at 0.2 micron. These recent advances in technology help further reduce production downtime and maintenance costs. Even though high-quality filters may cost more initially, their total cost of ownership comes down substantially each day they remain in use.

Work with a professional filtration partner

When Donaldson helped the yogurt processor install to cartridge micro-filtration for its manufacturing line, there was collaboration from start to finish. Donaldson provided laboratory analysis of water quality, tested various micron grades to determine the right balance of pre-filter protection, and provided product expertise regarding proper steam sterilization to help extend micro-filter life.

Micro-filtration is an effective, 3-A compliant method for producing pasteurized-equivalent water and clean, dry compressed air. Because your production lines are under heavy demands, work with a qualified filtration company to achieve the best performance and value from your sterile filtration system. They can help you understand your facility risks and help design the right locations and sequence for filtration. They can also provide products and technology that help keep your product recovery systems in operation at a lower overall cost.

To get in touch with a Donaldson Process Filtration specialist, contact us today.

-160x160-state_article-rel-cat.png)

-205x205.jpg)

-205x205.jpg)