Ensuring a safe workplace isn’t just about following protocols; it’s about equipping oneself with the right tools and knowledge. This article delves into workplace safety, emphasising the importance of quality industrial hardware tools.

Essential Safety Gear

Safety gear acts as the first line of defence against potential hazards in an industrial setting. Beyond the basics like safety goggles and steel-toed boots, there’s a wide array of equipment tailored for specific tasks. Respirators, for instance, protect against inhaling harmful fumes, while specialised gloves can shield hands from extreme temperatures. It’s essential to understand the unique risks of each task and equip workers with the appropriate safety gear to mitigate those risks.

Abrasives

Abrasives are tools used for grinding, polishing or cleaning surfaces. The right abrasives can make tasks not only more efficient but also significantly safer. Quality abrasives, sourced from reputable hardware suppliers, are designed to offer uniformity and durability. This uniform performance ensures that the abrasive doesn’t break or malfunction unexpectedly, which can lead to accidents. Moreover, high-quality abrasives reduce the effort required by the worker, minimising fatigue and the associated risks.

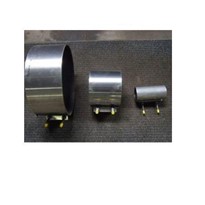

Fasteners

Every structure, be it a towering skyscraper or a simple workbench, relies on fasteners. A structure’s integrity is paramount. Quality fasteners ensure that every part of a structure remains securely in place, preventing unforeseen collapses or failures. Fasteners from trusted hardware suppliers are crafted to resist corrosion, wear and tear. This ensures that structures remain stable for longer periods, reducing the need for frequent maintenance or replacements.

Hand Tools And Power Tools

Hand Tools

Hand tools, often seen as the simpler cousins of power tools, demand respect. While they lack the complexity of their powered counterparts, misuse can lead to injuries. It’s vital to ensure that these tools are free from defects, rust or damage. Moreover, using the right tool for a specific task ensures efficiency and safety.

Power Tools

The realm of power tools is vast, from drills to electric saws. While they speed up tasks, they also introduce additional safety concerns. It’s imperative to ensure that workers are adequately trained, the tools are regularly inspected and safety guards are always in place.

Both hand and power tools benefit from regular maintenance. This not only ensures their longevity but also guarantees that they operate safely. Regular inspections can identify potential issues before they escalate into safety hazards.

Welding

All welding should be conducted in a controlled environment with proper barriers and signage can prevent unauthorised or untrained personnel from entering potentially hazardous welding areas. Regularly inspect welding equipment for wear and tear. Quality welding tools, sourced from reliable suppliers, offer consistent performance, reducing the chances of unexpected issues. Beyond the standard welding helmets and gloves, consider flame-resistant clothing and safety footwear to protect against sparks and molten metal.

Don't Compromise On Quality Or Safety

At Wilson’s Industrial Sales, we’re more than just an industrial tool supplier. We’re your partner in ensuring your workspace is safe and efficient. We stock state-of-the-art hand and power tools, abrasives, fasteners, safety gear, welding accessories, tapping, threading and drilling equipment. So, don’t compromise on safety. To speak to our expert staff, give us a call today.

-160x160-state_article-rel-cat.jpg)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)