The unique construction of the JS Lamella pump enables it to pump large and hard particles such as bones, tissues and fat.

There are many scenarios where transferring solid materials WITHOUT adding liquids is required. The JL Lamella pump makes it possible to pump an inhomogeneous product over long distances. One example would be food processing when pumping thick consistency foods like minces or vegetables to make patties. These consistencies must be mixed to a particular recipe that cannot take further moisture. Another example would be transporting bone and offal in an abattoir or meat process plant. The transportation of pre-broken bone and offal can be a costly area of production, which can be simplified and more cost-effective. The pre-broken product can be transported [un-manned] within fully enclosed pipelines. The closed pipe system reduces hygienic problems and odours.

Because of the pump’s compact design and ability to pump in a closed pipe system, the JS Lamella Pump replaces other systems such as screw conveyors, progressive cavity pumps, pressure tanks and conveyor belts.

The enclosed pipeline system ensures more sanitary conditions. The product is much less likely to be contaminated by insects, dust or water (rain). This cannot be guaranteed when using screw conveyors or manual transfer systems like forklift and bins.

The Lamella pumps also reduce labour and maintenance costs for operation in comparison to a blow tank or manual system. A manual transfer system requires a manned forklift, which also brings into play wear and tear on the forklift, increases OH&S risks and increases the chance of equipment damage. Using a blow tank system requires an operator, and this system also requires the addition of water, which needs to be cooked out of the product, using more fuel than that required for a JS Lamella pump transfer system. Maintenance on a screw conveyor can get expensive. Re-welding flights, straightening screws, wear on the flights are all maintenance issues for screw conveyors transporting tough materials like cattle bones. Also, when distances become too long, a screw conveyor becomes less economical and more problematic.

Additionally, the Lamella pump has lower energy and maintenance costs, as well as a higher capacity, in comparison to other systems. The JS Lamella Pump doesn’t require any manned operation, which reduces the risk of injuries.

If the right choice is a pump, to keep the product in an enclosed pipe system and/or transport longer distances, then a JS Lamella should be the choice. Advantages of a JS Lamella over “comparable” pumps are as follows:

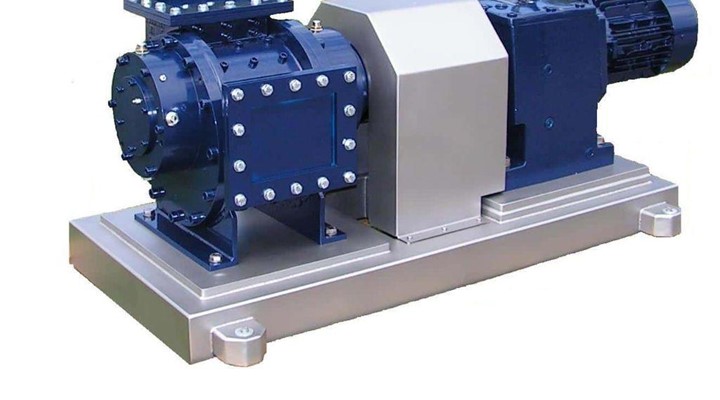

- All wearing parts are replaceable on JS Lamella pumps.

- Top and Bottom plates wear much slower than cam discs, so they only need replacing every 4-5 times the Cam discs are replaced. In “similar” pumps, the top and bottom plates are part of the cam disc arrangement, meaning repairs are more expensive than with JS Lamella pumps.

- Wearing bars are bolted to the rotor so that no material can lodge between the rotor and the wearing bars. If they are not bolted (like on competitor pumps), pumped material can squeeze between wear bar and rotor, pushing the wear bar onto the Lamella. This causes premature wear and jamming of Lamella’s.

- A standard Lamella pump is designed with Mechanical seals, which take up less space than other seals (like rotoglyde seals and gland packing). Mechanical seals guarantee a 100 % seal. They also protect the bearings better from product ingress.

- On a JS Lamella pump, the shaft end and rotor are assembled with 8 bolts, which are tightened to a specified torque. On “similar” pumps the rotor and shaft end are bolted but also welded together. By not welding those 2 parts, it is much easier to disassemble the parts for service and increases service life.

- Key wearing parts like the rotor, Lamellas, wearing plates, cam discs, top- and bottom plates and wearing bars, can be supplied in tool steel quality stainless steel, with high strength, wear-resistance and excellent corrosion resistance.

- JS Proputec Lamella pump customers (who have also used “similar” pumps), claim that JS Proputec wear parts are stronger and last longer than the competitor pump/s. The difference is even greater when the pumps are used for hard and tough materials (such as cattle bones).

A proven suitability for many purposes is verified as the pump is installed in industries within fish-processing, animal rendering and pet food, as well as slaughterhouses all over the world.

The pump is available in several different versions, thus enabling a perfect fit to your specific production needs.

-160x160-state_article-rel-cat.png)