Not all Cable Ties are created equal! Is it all just marketing spin, or are the differences between the lower & higher cost ties worth considering? We stock an enormous range of cable ties that vary in size, capabilities, certification and of course, price. Sometimes it can be daunting to figure out what will be the best to use in your next project.

Standards are constantly evolving. For example, in 2016 a set of new “type” designations for cable ties and fixing devices were introduced. In particular, the designation “Type 21S” include the recognition of certain performance criteria, as well as the recognition of the raw material used to make them. In practice, “Type 21S” defines products suitable to support flexible metal conduits and cables in construction, in accordance with the applicable installation codes.

If you are not sure which standards are relevant for your application, please feel welcome to contact one of our experienced product specialists.

Comparison: High Quality NPA Ties Vs Generic 'Low Cost' Ties

| Quality NPA Cable Tie | Generic Alternative | |

| Extreme Weather / Environment | Maintains its strength over time, regardless of fluctuating temperature and humidity of its environment. | More likely to become brittle and weak in harsh environments. |

| Outdoor (UV) Performance | Specialised ties are made of UV resistant materials. | Will disintegrate faster when exposed to sunlight. |

| Advanced Certification |

Ties designed for specific applications (eg in marine or solar power environments) will be certified according to that industry's relevant certification/s. | Generic ties rarely have genuine certifications and are sometimes outdated. |

| Marketing and Product Information |

Quality ties have clear product information that articulates relevant specifications of the product and its certifications. | Packaging and marketing is usually unspecific about properties such as material and tolerances. |

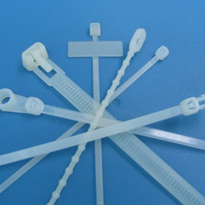

Key Features of NPA Quality Nylon Cable Ties

Here are some of the key features found in many of our professional-grade nylon cable ties.

Beyond Nylon

In recent years in Australia there has been an explosion of solar PV installations. Standard nylon 6/6 ties just don't cut it when it comes to outdoor usage and will deteriorate rapidly. For outdoor applications there are two main alternatives - nylon 12 and stainless steel. While their cost may seem significantly more than nylon 6/6, after factoring in the cost of replacement every few years compared to a good quality steel tie that can last 20 years or more, then clearly the nylon 6/6 tie can quickly become the expensive choice, not to mention the damage to your business reputation!

Our stainless steel cable ties, bands and buckles are made from marine-grade 316 stainless steel with high resistance to hostile environments eg. corrosive chemicals, temperature, UV radiation & abrasion.

Typical applications: marine, indoor, outdoor, heavy industrial areas, underground applications, electric and solar power facilities.

We also offer an epoxy-polyester coated version of each stainless steel cable tie which can provide additional surface protection and a barrier to resist corrosion between dissimilar metals.

Conclusion

While using cheaper, generic ties can sometimes result in small cost savings, we think that many commercial and professional applications are better served with cable ties that hold relevant certifications, are specifically designed for the prevailing conditions and are designed for optimal usability by commercial installers.

-160x160-state_article-rel-cat.png)