Major fresh produce supplier Montague's reputation has seen them work with many leading food producers to store and distribute household brands, producing product that refreshes, inspires and satisfies.

Dedicated to delivering the absolute best in Australia’s fresh produce, they have always sought to implement the latest technology, such as introducing the first Controlled Atmosphere (CA) storage into Australia in 1967.

Introduction to the Bio Turbo Solution

However, like any other fresh food supplier, Montague are not immune to dealing with post-harvest spoilage and wastage of product, which is often a natural by-product of the environment that fresh produce is typically stored in.

In what proved to be a timely occurrence, the team at FreshView approached Montague with a solution to help overcome these challenges - the Bio Turbo solution.

Manufactured by Miatech, Bio Turbo’s patented four-stage purification system significantly reduces airborne bacteria, ethylene gas, mould spores and odour from any cold storage facility, making for longer lasting, fresher quality produce.

Putting the Technology to the Test

Before committing to rolling out the Bio Turbo solution across any of their facilities, Montague wanted to conduct, investigate and analyse the effectiveness of the Bio Turbo technology under simulated commercial conditions.

The aim of this investigation would be to quantify the difference between a control, and a Bio Turbo-treated replicate. This would involve the tracking of total kgs /dollars of product at the commencement of the trial, versus the amount of product that was totally spoiled after a given period of treatment.

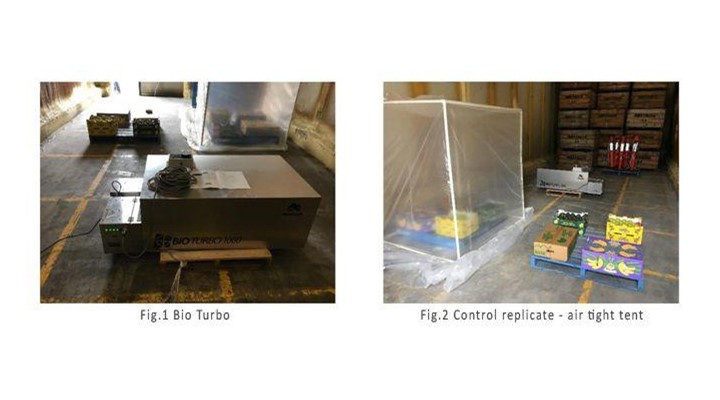

The treatment replicate consisted of a 73 kg pallet of various fresh produce samples (valued at $179) left in a cold room in an atmosphere treated by the Bio Turbo unit (Fig.1).

Acting as the control replicate, an air tight plastic tent was erected, which created an untreated atmosphere (Fig.2). This replicate, (also 73 kg) was sealed prior to turning on the Bio Turbo unit to ensure the atmosphere was not treated.

Other variables such as temperature and humidity were consistent between replicates to ensure no premature conditioning or ripening would occur.

This was also done to prevent any unnecessary chilling injuries of the climacteric fruits, which may in turn result in unrepresentative levels of breakdown or spoilage.

The Results

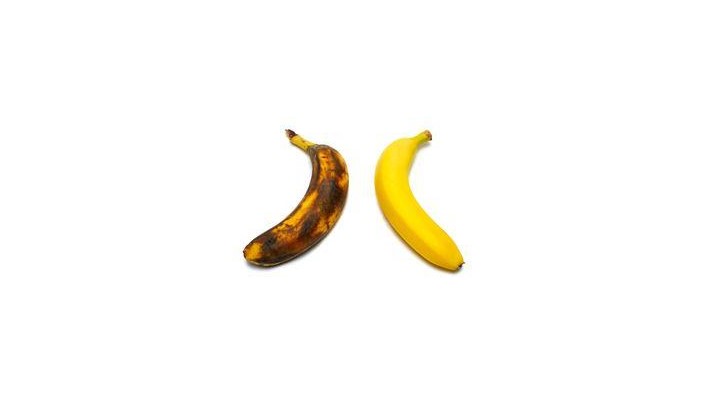

After the trial, conducted over a period of 16 days, the total kgs of produce lost in the control replicate was 15.16 kgs, equating to a value of $74.30. In the Bio Turbo treated environment, produce loss was only 7.85 kg valued at $38.50.

Montague have reported that they have certainly been impressed with the results seen from the Bio Turbo unit. There was roughly only half the spoilage from produce treated by the Bio Turbo solution, compared with produce that hadn’t been.

The impact of this saving over the entire season is going to deliver a rapid return on investment for Montague.