The Problem: A traditional refrigerant based air conditioner was installed on wastewater clarifier controls but could not withstand the harsh chemical environment of the wastewater industry. During the hotter months of the year, controls on a wastewater clarifier process that were mounted outdoors were experiencing weather related overheating problems. Not only did higher temperatures compromise the performance of the traditional refrigerant based air conditioner, the corrosive environment from the many different wastewater chemicals, acids and bases prematurely wore the critical moving parts of the air conditioner.

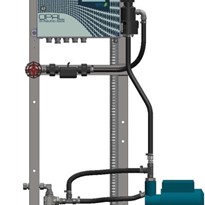

The Solution: A model 4850SS-316 Dual Cabinet Cooler System was installed providing 3,400 Btu/hr (997 Watts) of cooling for the clarifier controls, keeping them running efficiently. The Cabinet Cooler is resistant to seasonal temperature fluctuations because it operates from a source of compressed air not ambient air. The 316SS construction also provided high corrosion resistance to the chemical environment and maintenance concerns were eliminated due to the Cabinet Cooler having no moving parts.

Comment: The inherent reliability of the vortex tube operated Cabinet Cooler System is another important advantage in this application. Because they have no moving parts, EXAIR Cabinet Coolers are virtually impervious to hostile environments. Wastewater treatment, chemical processing, paper manufacturing, steel mills and power generation are just a few of the facilities benefiting from this simple, yet effective technology.

-160x160-state_article-rel-cat.png)