The challenge: Previously the rapid production process – consisting of 6kg packages of product – was carried out by two operators. The work was manually intensive and the lifting was a potential safety hazard. A forklift regularly had to move and adjust pallets. The safety risk as well as the cost of the manual handling were evidently a problem that needed to be addressed.

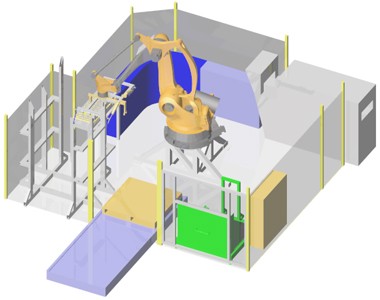

The solution: The KUKA KR100PA palletising robot was ideal in reach and adequate in speed, its lightweight arm with long reach allows rapid movement of product from the infeed to its position on the pallet.

The KUKA KR100PA is a 4 axis-palletising robot. It is designed with an envelope (area of reach), which comfortably services several positions in the cell; picking a pallet, picking cardboard, picking up the product and placing it on a pallet.

Factories with high volume product that needs to be palletised are best candidates for palletising robot cells, particularly if they have manual packing of pallets. And also those that produce high volume packaged goods, particularly food products with products in regular cartons are ideal with oddly shaped product also attainable.

The results: The KR100PA it’s a robot that is extremely well suited to the job. After installation of the robot, the costs and safety risks of the three palletising operators were removed. The pallets were stacked more neatly and there was less forklift activity in the area. Additionally, the system allows for for future demands in line capacity.

Wherever there are repetitive tasks that are being done by operators, the possibility of a robot should be investigated. Robots are able to do repetitive work with ease and at very little on-going cost after the initial installation. If any future changes occur in the process, robots are easily programmed to handle the new situation. Robots can be made intelligent to some extent with the use of optical sensors, torque-sensing and reading product barcodes. A side benefit to the installation of a robot cell is that it often leads to improving efficiencies in neighbouring equipment, as poorly presented product is not tolerated by the robot.

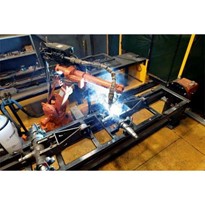

About Engenius Solutions: Engenius Solutions are automation integrators. They have been around since 1997, and specialise in designing and installing turnkey robot cells that have solved challenging problems in a wide variety of fields. Projects have included processes such as ceramic grinding, plasma cutting, press tending, plastic moulding machine tending and painting. See www.engenius-solutions.com.au/

For more information on how KUKA robots can enhance your business, contact Headland Machinery today on 03 9244 3500, email sales@headland.com.auor visit www.headland.com.au/kuka