Residual Magnetism occurs when a magnet fails to turn completely off. The magnetic flux is a result of a circuit being created between the rare earth magnets inside and the steel body of the magnet. The level of Residual Magnetism depends on the Shunting Technology and the overall design of the magnet.

These next 3 magnets are a good example of Residual Magnetism found in lifting magnets and why magnets with no Residual Magnetism are the safest option:

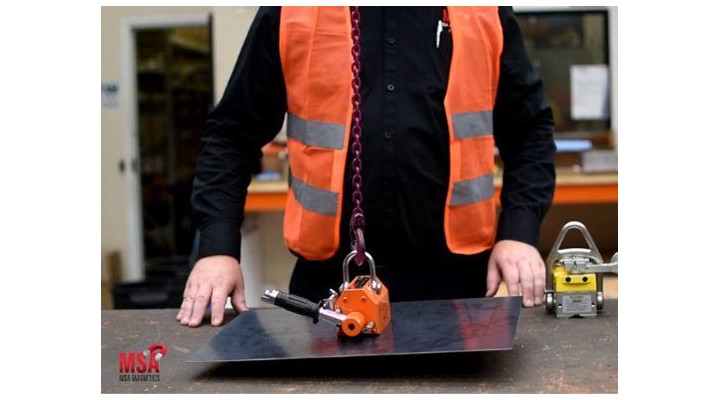

Extreme Residual Magnetism

- The 1st magnet has quite extreme Residual Magnetism, which will cause the magnet to collect ferrous particles and debris even after it has been turned off

- Debris will likely cause an air gap on subsequent lifts and may permanently score the magnet. This can significantly de-rate the magnets SWL (Safe Working Load) and the magnet could fail a pull test

- High risks of hand injuries if the operator uses their hands to separate the magnet from the load

- The material being handled will also be damaged by any debris stuck to the magnet

Low Residual Magnetism

- This magnet is a good quality Passive Shunting magnet. It has a small amount of Residual Magnetism, although not enough to risk hand injuries

- Will still require regular inspection for debris, however, you can expect it to collect much less than the first magnet

No Residual Magnetism

- The 3rd magnet uses Active Shunting Technology which allows it to be turned 100% of the way off

- It is the safest type of magnet and is also unlikely to collect any ferrous debris after being turned off

- In the event of damage to the working surface, replacement pole shoes can be fitted safely and easily using basic tools in your workshop

MSA Pro-Lift and Magswitch Lifting Magnets are designed to have a clean break of magnetic flux at the OFF position. We ensure the highest industry safety standard of our industrial Lifting Magnets while making sure they are easy to use!

Need a better understanding? Contact our magnet experts today.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)