“We estimate a productivity gain of 25% and more than a halving of the labour costs,” explained Greg McCarthy, Cream Process Co-ordinator at the plant that produces the Bulla branded liquid dairy products. Explaining the labour savings, since the upgrade to the semi automatic Flex Pack IBC filler, Greg said that only one person was now needed for the filling of an IBC, whereas two were needed with the superseded manually operated system. And, in addition, the one operator having started the filling process, with the press of a button, can go off and attend to other machinery while the IBC fills with cream or yoghurt products. “We use about 14 IBCs a day, despatching them to businesses in food service so the labour saving is a very significant issue… a major cost saving resulting in a short payback time,” added Greg.

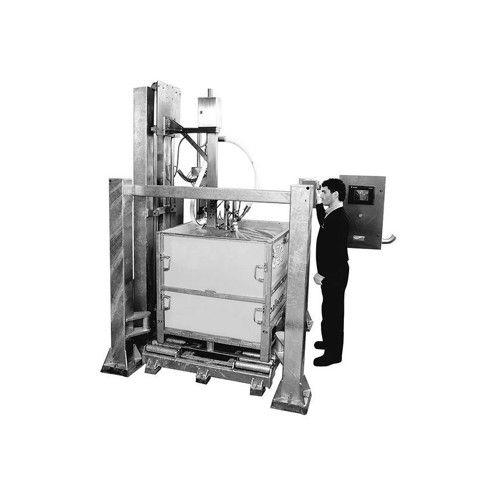

With the old filler it was a manual connection to the IBC’s filling hole and there was also a need to measure the level of cream in the IBC with a measuring stick, to ensure the correct amount of cream had been loaded. Regal were also looking for a semi automated procedure … because the filling process for the superseded unit required use of a short step ladder, to work at the required height, and the use of a measuring stick was not the best way of ensuring a contamination free product. Now, with the new filling process operators are not required to climb, are protected by a light curtain from moving parts, and up to a suitable with weigh cells, the volume of cream in the IBCs can be monitored instantly and progressively. A touch pad control system, based on PLC controls, includes a ability to manually override volume and timer settings. This can be needed when part filling an IBC to complete an order.

With less labour, automatic filling as well as the new system meeting the current AS 4024 safety standard, there has been an improvement in Occupational Health and Safely standards. “It’s been one, two and then three advantages for us, since the arrival of the Flex Pack filler,” said Greg. The Flex Pack IBC filler has a clean in place system and all components that come in contact with food are made from 316 grade stainless steel or other food grade materials. For other bag filling applications requiring special treatment there is a bag evacuation and a gas or liquid purge system available as an optional extra. Filling speed is up to 10 x 1000 litre IBCs per hour, depending on product supply conditions with a fill range of 200 to 1,400kg.

Flex Pack supplied IBC liquid fillers are suitable for the food wine and beverage industries as well as companies producing bulk quantities of liquid cleaning products and pastes.