Mining sites require tyre protection chains on loaders to last longer and reduce downtime. However, the process of ordering tyres, getting them ready for protection chains and then installing the chains is a long process, which according to Macmahon involves:

- Ordering tyres from a supplier

- Sending tyres to another company to be shaved down to size

- Getting chains fitted at another place

According to Macmahon, this process is not only time-consuming but expensive. In addition, it is not environment friendly because the rubber shaved off from the tyres end up in landfills, contributing to waste. Macmahon found a way to improve sustainability practices by manufacturing custom tyres by teaming up with BKT Tires and TradeFaire International and RUD Chains to create the world’s first custom loader tyre.

The rolling circumference of the new tyre was ideal to fit RUD tyre protection chains, reducing the time used to shave the tyres and downtime.

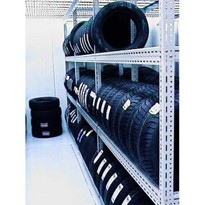

In the picture is the Macmahon loader tyre in front of RUD Chains Perth office. For more information on RUD Tyre Protection Chains, check our website page or click here to send us an enquiry.

Article copyright to Macmahon, read the full article on the Macmahon website here.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)