The business has been operating with previous generations of the Kato range, and never had a failed component says owner Paul ‘Smiley’ Williams.

Williams Cranes & Rigging started in 1992. Founder and owner Paul ‘Smiley’ Williams started in the lift industry as a lift fitter and welder. Today, Williams Cranes operates from its depot in Pinkenba Queensland and predominantly supplies wet hire crane services to South East Queensland area. Dry hires of cranes and lifting equipment are also available across Australia and PNG.

“After completing my trade, I started as a lift fitter and welder for Johns & Waygoods – I enjoyed climbing, working at heights and helping the crane crews that would come out to my jobs. One of the guys suggested I get a job rigging. I got a job as a rigger and after putting in the work I went on to get my crane ticket,” said Smiley.

“I was working as a top hand rigger in Western Australia and when the contract ended, I came back to Brisbane and decided to buy a crane and started working in steel erection. I started Williams Cranes & Rigging with a Coles Hydra Husky which had a capacity of 16.5t. The business has grown since then and we now run a fleet of 27 cranes. We also run the trucks and trailers needed to support the crane fleet and which transport the counterweights and associated lifting equipment.”

“Our largest crane is a 100t capacity all terrain and we go right down to the two-tonne crawler cranes. We run a number of brands including Liebherr, Demag, Kato, Tadano, Maeda and Franna’s.”

The Impact of Kato City Cranes on Williams Cranes & Rigging

“We’ve been operating the Kato city crane range, in one form or another, and have gone through two generations of Katos over the last 20 years. We have recently upgraded our 13t and 20t Kato city cranes. We have now added the new 25t capacity machine to our fleet, where we also have a 20t Kato rough terrain crane.”

“What do we like about the Kato? They are incredibly reliable and operator-friendly. They are also well-engineered with great hydraulics. What have they done for our business? They have worked in numerous applications including construction, steel erection and the petrochemical chemical sector. With the small footprint, they are ideal for getting into tight locations, but they still offer plenty of lifting capacity,” he said.

“In my opinion Kato are built with traditional Japanese engineering values. They feature the latest technology, but they are constructed with a strong focus on the engineering which makes for a fundamentally ‘sound’ crane. For me, and I’m going back 40 years, everything to do with Japanese cranes is focused on reliability and longevity. Kato’s work hard, and over a long period of time.”

“They are great all-rounders for us. They are ideal for residential construction where site access can be limited. They have worked in the petrochemical sector in plants where there isn’t easy access for the lift. We’ve also put in swimming pools with the Katos; they are a great little taxi crane. We’ve had them pretty much doing anything and everything; they are a very well-utilised asset for us. Also, the fly & needle on the Kato are amazing, you are able to rig the fly in minimal area. The fly has a telescoping needle which is extremely smooth to operate.”

Williams Cranes & Rigging’s Relationship with Tutt Bryant

“With the new CR-250Rv we worked closely with Peter Lawgall and his team at Tutt Bryant Equipment. Their service was excellent, and they are great to deal with. Whenever you need something, they are there. They answer their calls and they do what they say they are going to do. They know how to look after you,” said Smiley.

“We have had a long relationship with Ian Eyres and when Peter came into the sales team, the excellent relationship continued. He does a wonderful job of running the sales team and supplying excellent machines.”

“We have worked with Tutt Bryant and earlier Kato distributors for decades. We have always had good relationships with all the departments at Tutt Bryant, including sales, product support and parts. Each team has great communication skills and always keep us in the loop whenever any of our cranes have an issue,” he said.

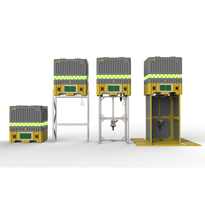

Kato City Crane CR-250Rv

The CR-250Rv is the largest two axle city crane available on the Australian market and takes the Kato city crane range to a whole new level. The focus with this model is on strength, technology, safety, speed of operation, and ease of operation in small spaces. This model is the flagship of the Kato city crane range, complementing the CR-200Ri and the CR-130Ri. Featuring several significant changes to meet Australian requirements (including EN13000).

This new addition is supported with a full Kato factory warranty and national support through Tutt Bryant Equipment’s extensive service and spare parts network.

The CR-250Rv features a new boom and jib, “EJIB” which is designed for deployment in very narrow spaces. It is the first CR model mobile crane equipped with the EJIB which is based on the Kato 4S concept.

Two of the crane’s biggest features are the EJIB mechanism and a hydraulic luffing and telescoping fly which takes a single operator 10 minutes to ‘swing’. Ordinarily on manual operations, two workers are required to swing a standard luffing fly with setup time of 10 minutes for a single operator.

New Fully Hydraulic Fly Jib

The Kato super luffing fly jib has only previously been available on the 35t city crane (Japanese domestic model). It is now fitted as standard on the CR-250Rv, bringing maximum rated lifting height, boom plus jib to 38.4m. The fly jib hydraulically telescopes from 5.3m to 8.2m and can be mounted within a 5.7m area from the slew centre. It is fully powered with the ability to telescope and offset under 100 per cent load.

Ergonomic Cab

The cab impresses with an all-round excellent view and provides outstanding comfort to the operator due to the hydro-pneumatic suspension. Furthermore, it has a built-in IC tag providing high-level security, therefore reducing the risk of crane theft.

The Kato CR-250Rv features several advanced safety features to enhance safety during operation and minimise incidents.

- The Kato Automatic Crane System (ACS) – Automatic safety device that instantly responds to direct changes in operating configurations. It has a range of limiting functions that increase safety during operation. With its high intensity colour LCD, the new ACS makes operations easier as it provides illustrated key switches, enabling quick identification of their functions for each operation.

- Touch Screen (COR) Display, Data Logger – Information such as fuel consumption, operation hour, are available on display. It includes ECO switch to save fuel by adjusting for optimum work engine speed during crane operation. During non-operation, the hydraulic pump outlet and fuel consumption are also greatly reduced thanks to the Auto-Minimum-Control adoption.

- Large Size Display Screen – Terrific all-round vision of the site. 3 times wider than the previous model giving operator a clear display during operations.

Optional Features

The two positional offset Searcher Hook is a breakthrough feature for inserting operations. This feature performs best where the height is limited including applications featuring warehouses, balconies, and soffits.

Other optional features include anemometer, tyre pressure monitoring system, door visor, lunch table, resin/aluminium outrigger plate and storage, and remote-control camera cleaner.

Smiley and his wife Lorna play active roles in the Queensland branch of the Crane Industry Council of Australia. Smiley describes their passion for the industry.

“Lorna is an active member in CICA Queensland and as industry body, CICA plays a vital role in our industry. Businesses that are reputable will not be members. CICA sets standards and is a good benchmark for the industry. Initiatives like CraneSafe and CrewSafe are important as well.”

“Trainess, training, and apprenticeships is probably the most important issue facing crane hire businesses, and the industry as a whole. We need to bring in new blood, but the training needs to be right. Crane driving is very different in Europe and the US and the standards are much higher in these markets compared to Australia. CICA is working hard to address this and raise the standard,” he said.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)