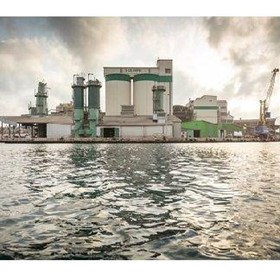

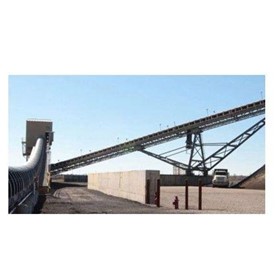

Bulk materials like cement has to be conveyed in large quantities via motorways and railways. They are often loaded at the production location in suitable vehicles and transported as bulk cargo to other locations.

Bulk Loading Heads

Bulk materials like cement has to be conveyed in large quantities via motorways and railways. They are often loaded at the production location in suitable vehicles and transported as bulk cargo to other locations.

LOADING HEADS FOR BULK TRANSPORTER VEHICLES

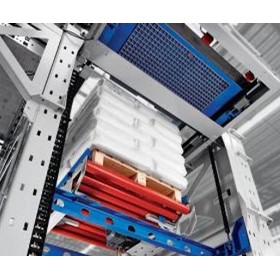

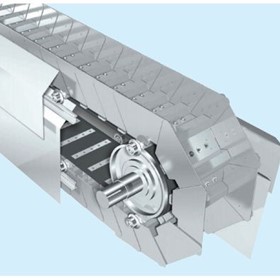

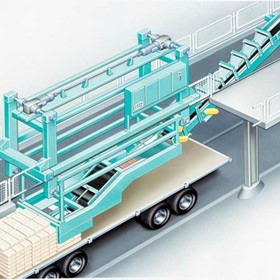

Bulk transporter vehicles can be loaded quickly and free of dust with the BEUMER bulk loading head. It is designed according to the double-wall system, i.e. the material inlet and the dedusting unit are separated from each other. The bulk loading head has to be connected to a dedusting air system. The hoist equipment is either a motor cable winch or a hand-operated winch. Material feed must be metered. An operator panel is used for operation.

When placing the bulk loading head on a silo inlet, the sealing cone is lowered and opens the outlet spout. The fill level in the vehicle is adjustable due to the variable lowering level of the sealing cone. In order to balance out any minor positional deviations of the vehicle, the bulk loading head can be moved laterally during placement. When the loading process has been terminated, a vibrating motor shakes off any material still adhering to the unit in order to avoid soiling of the vehicles.

Wide range of products for a different range of applications

Efficient and ecological loading

Individually adjustable loading systems

To contact BEUMER Australia about Bulk Loading Heads use Get a quote.

Bulk materials like cement has to be conveyed in large quantities via motorways and railways. They are often loaded at the production location in suitable vehicles and transported as bulk cargo to other locations.

LOADING HEADS FOR BULK TRANSPORTER VEHICLES

Bulk transporter vehicles can be loaded quickly and free of dust with the BEUMER bulk loading head. It is designed according to the double-wall system, i.e. the material inlet and the dedusting unit are separated from each other. The bulk loading head has to be connected to a dedusting air system. The hoist equipment is either a motor cable winch or a hand-operated winch. Material feed must be metered. An operator panel is used for operation.

When placing the bulk loading head on a silo inlet, the sealing cone is lowered and opens the outlet spout. The fill level in the vehicle is adjustable due to the variable lowering level of the sealing cone. In order to balance out any minor positional deviations of the vehicle, the bulk loading head can be moved laterally during placement. When the loading process has been terminated, a vibrating motor shakes off any material still adhering to the unit in order to avoid soiling of the vehicles.

Wide range of products for a different range of applications

Efficient and ecological loading

Individually adjustable loading systems

To contact BEUMER Australia about Bulk Loading Heads use Get a quote.

Thanks for your help!

Sorry! Unable to submit your request at this time. Please try again later.

Report this product