This innovative solution not only resolved the initial challenges but also laid the foundation for improved productivity, safety, and customer satisfaction. This successful case study serves as a testament to the power of advanced automation and integration in modern warehouse management.

Customer Requirements

Streamline warehouse operations, improve stock management, enhance safety, and integrate seamlessly with ASRS (Automated Storage and Retrieval System)

Benefits

Enhanced Operations

The warehouse transitioned to a 24/7 operation, significantly improving operational efficiency.

Streamlined Stock Management

The 3D visualisation feature made stock identification and retrieval simple and efficient, reducing the time taken to locate items.

Autonomous Order Fulfilment

The system enabled seamless and autonomous order processing, further expediting customer deliveries.

Optimised Space Utilisation

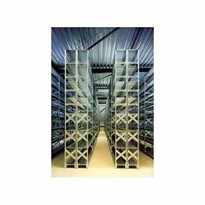

The AGVs and ASRS shuttle system collaboration maximised warehouse space utilisation with a gain of 2 – 3 times the volume of pallets utilising the same footprint.

Enhanced Safety

The organised storage system also reduced safety risks with tall pallet stacks no longer required and more space available, forklift-related incidents have been reduced.

Challenges

The client, a prominent distributor in the logistics industry, faced significant operational challenges in their existing warehouse facility. The lack of organisation and haphazard arrangement of pallets resulted in inefficiencies, with difficulties in locating stock leading to unnecessary delays and increased manufacturing costs. Safety concerns arose from tall pallet stacks and incidents of forklift operators damaging racking structures.

System Installation

A phased approach was adopted to firstly integrate the new AGV (Automatic Guided Vehicle) system with the ASRS shuttle system, and secondly, the transition of the entire warehouse inventory into the new system without interrupting ongoing operations.

AGV Deployment

A fleet of four MAXAGVs was introduced into the facility to autonomously navigate the warehouse environment, retrieve, and transport pallets of product (sometimes x2 high) with precision.

Inventory Transition and Scanning

All existing stock was systematically removed and scanned into the new Warehouse Management System (WMS). This process enabled accurate tracking of each item while ensuring uninterrupted warehouse functionality.

Pallet Scanning and Placement

Pallets arriving from the manufacturing area were scanned to allow the WMS determine the optimal rack location for each piece of stock, enhancing storage density and accessibility.

AGV Stock Movement

The AGVs then seamlessly transported the pallets to the designated rack location and commanded the ASRS shuttle system to store items logically in the up to 22 deep rack positions, maximising warehouse space utilisation.

Order Fulfilment Automation

The AGV system facilitated autonomous order fulfilment. Upon receiving an order, the AGVs efficiently retrieved the required combination of stock types and delivered them to the outfeed area, streamlining the order process.

3D Visualisation

The incorporation of a 3D visualisation component within the new WMS enhanced visibility and navigation within the warehouse and can be easily viewed on smart phones, pads and laptops.

“I am extremely satisfied with the efficiency and reliability of our automated warehousing solution. The after sales service and technical support provided by the RA team has been exceptional.”

Domenic Tacca - Managing Director, Tacca Industries

-160x160-state_article-rel-cat.png)